Mimaki TX500P Dye Sublimation Printer

$288,745.00

Unleash the Power of Soft Signage & Home Furnishing Printing

Go big and go bold with the Mimaki TX500P-3200DS.

This super-wide dye-sublimation printer delivers unmatched speed, exceptional quality, and unmatched versatility, powering up your production of soft signage, banners, and stunning home furnishing textiles.

Boost your efficiency, expand your capabilities, and impress your clients with vibrant, professional-grade results

Available on backorder

Mimaki TX500P Dye Sublimation Printer: Supercharge Your Soft Signage & Home Furnishing Production

The Mimaki TX500P-3200DS dye-sublimation printer unlocks a new level of productivity and versatility for producing stunning soft signage and home furnishing textiles.

This powerhouse printer boasts a super-wide 3.2-meter print width, blazing-fast speeds of up to 130 sqm/h, and a unique simultaneous printing and fixation capability, revolutionizing your wide-format printing workflow.

Unmatched Speed and Efficiency:

- Maximize production with industry-leading print speeds of up to 130 sqm/h for 4-color printing, significantly reducing turnaround times.

- Say goodbye to bottlenecks with the innovative one-stop printing and fixation process, eliminating the need for separate heat transfer equipment.

- Minimize downtime and waste with reliable continuous printing and automatic media feeding/take-up systems.

Exceptional Print Quality for Demanding Applications:

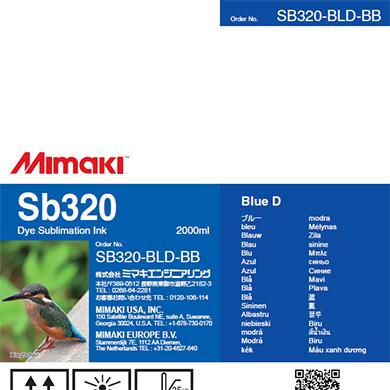

- Achieve vibrant, photorealistic colors with Mimaki’s Sb320 sublimation inks, delivering stunning visual impact.

- Maintain consistent quality at high speeds thanks to the advanced 12-printhead configuration and precision dot control.

- Handle diverse textiles with confidence, from lightweight fabrics to heavyweight banners, with adjustable print modes and media handling capabilities.

Designed for Seamless Workflow and Operator Comfort:

- Simplify operation with the intuitive user interface and user-friendly features like automatic nozzle cleaning and ink level monitoring.

- Maintain a clean and safe printing environment with the enclosed media compartment and optional fume extraction system.

- Ensure operator comfort with the height-adjustable control panel and ergonomic design.

Investing in the Mimaki TX500P-3200DS means:

- Unparalleled printing speed and efficiency for high-volume production

- Superior print quality for professional-grade soft signage and home furnishings

- Versatile performance to handle diverse textile applications

- User-friendly operation and a comfortable working environment

- A robust and reliable solution for long-lasting value

Printing and color fixation combined in a single printer unit

As the printer has a built-in color fixation device, Tx500P-3200DS enables printing and color fixation processes in a single printer unit. This feature considerably reduces production time and increases business opportunities.

The maximum printing speed (130 m2/h) achieves high productivity

The maximum printing speed is 130 m2/h*1 for 4-color printing and 105 m2/h*2 for 6-color printing.

The high-speed printing accelerates on-demand print production.

*1: 130 m2/h (4-color, high-speed mode, 540 × 360 dpi, Bi, Hi, 3 Pass)

*2: 105 m2/h (6-color, draft mode, 540 × 360 dpi, Bi, Hi, 4 Pass)

Mimaki’s superior print-image quality control technology achieves exceptional quality printing at high speeds on 3.2 m wide textile

- To deliver high-quality printing, a new AMF(*3) ensures stable textile feeding/take-up. Additionally, a pulling roller provides stable textile transportation by maintaining an appropriate pressure during printing onto rolled textiles with width of up to 3.2 m and weight up to 130 kg.

- Highly reliable inkjet technology optimizes the waveform to achieve precise placement of ink droplets onto media. The Mimaki Advanced Pass System 4 (MAPS4) reduces banding and uneven color printing. These features deliver exceptional quality printing at a high-speed.

Uninterrupted printing solutions

- Nozzle Check Unit (NCU) automatically detects and cleans clogged nozzles. Nozzle Recovery System (NRS) uses only unclogged nozzles as substitutes, when the clogged nozzles are not recovered after cleaning. These functions ensure constant printing performance and reduce printing waste owing to defective nozzles.

- The external ink supply unit is equipped with large (3 L) ink containers. Ink can be filled into the containers during the long-time continuous printing of a 3.2-m-wide, 300-m-long rolled textile.

| Weight | 3307 lbs |

|---|---|

| Dimensions | 221 × 71 × 72 in |

| Brand |

Mimaki |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.