Shop

Showing 1–16 of 72 resultsSorted by price: high to low

8017B Rollover Classic Flatbed Applicator

6717B Rollover Classic Flatbed Applicator

4017B Rollover Classic Flatbed Applicator

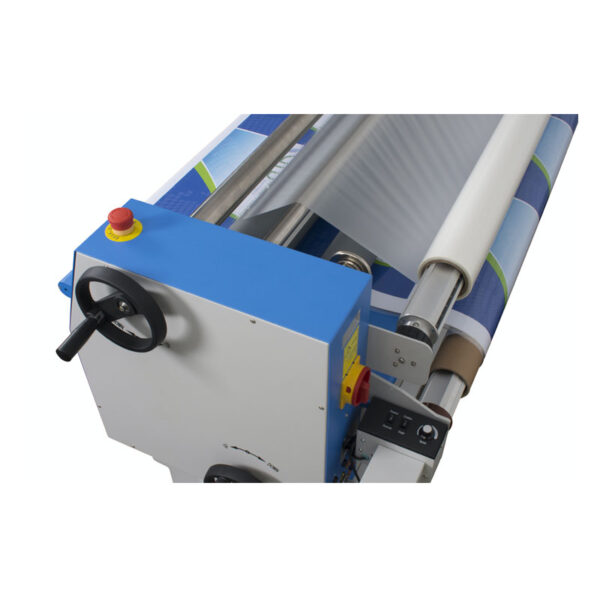

GFP Dual Heat Laminator 65″

For finishing professionals who need versatility, quality, and economy in one machine, the GFP 865DH-4RS delivers. Turn out thermal encapsulation with low melt films (1.5-10mil), PSA lamination, and mounting jobs quickly and easily.

Ultimate flexibility, fast and easy roll changes, and professional features such as Quick-Grip supply shafts, independent top and bottom heaters, web clutch adjustment, motorized rear rewind, and swing-up feed table come together in one industrial design, engineered to provide years of maintenance-free service. Ideal for signs, banners, posters, displays, boards, graphics, mounting, and much more!

3317B Rollover Classic Flatbed Applicator

F3315 RollOver Flexi Flatbed Applicator

GFP 663TH Top Heat Laminator

GFP 663TH: Supercharge Your Wide-Format Finishing

The GFP 663TH isn't just a laminator, it's a finishing powerhouse.

Laminate banners, signs, and graphics up to 63" wide at blazing-fast speeds with flawless precision.

Choose from hot air, hot wedge, or both to handle any material.

Stored settings, quick job recall, and integrated features like rewind and slitting maximize efficiency.

Invest in the 663TH for professional results and boosted productivity.

GFP's most advanced laminator with "Smart Finishing Technology" for the demanding Wide Format Finishing Professional.• Digital Microcontroller System • Color Graphic Operational Displays • Electronic Roller Gap/ Pressure Control • Swingout Unwind And Rewind Shafts • Inline Rotary Side Slitters • Top Roller Heat Assist • Integrated Rear Rewind • Roll Label Printer • Operator Warning Alerts • Onboard Operator Help TutorialsF2814 Rollover Flexi Flatbed Applicator

GFP 63″ Top Heat Laminator with Swing Out Shafts

MAXIMIZE PRODUCTIVITY

Inline Rotary Slitters

FAST ROLL CHANGES

Front/Rear Swing-out shafts

EASY LOADING

3" Aluminum Quick-Grip shifts

RUGGED DESIGN

Metal Alloy heaters

VERSATILE

Roll-to-Roll operation

GFP 63″ Top Heat Laminator

To make production easier and more efficient, the GFP 363TH features new 3” aluminum tube quick-grip film shafts with width measurements for easy loading and alignment, integrated top liner and rear output rewinds for roll-to-roll applications, and new metal alloy tubular heaters to reduce breakage. Ideal for signs, banners, displays, boards, graphics, mounting, and much more!

Foster On-A-Roll Lifter Motorized Lifting/Manual Movement

GFP 355 TH 55″ Top Heat Laminator

Foster Rotatrim PowerTech Series Trimmers

The PowerTech is a powered version of the Technical, operated by a foot pedal. Heavy-volume, large-format shops will see a quick return on investment through reduced manpower and increased productivity.

- The PowerTech frees both hands and decreases operator fatigue.

- The trimmer is electrically driven through a steel-reinforced belt for longevity.

- All-metal construction (and extruded aluminum baseboard, end frames and head) ensure robustness.

- An auto-lifting clamping mechanism locks materials into place as the head begins to cut, then automatically releases at the completion of the cut; prevents material and substrate scratching.

- A triple roller mechanism provides extreme down force for the cutting of heavy materials (maximum cut depth of 3mm).

If you’re looking for an “all day, every day-use” extremely heavy duty rotary trimmer that is capable of cutting the widest array of substrates and materials – from flexible to semi-rigid– this large format powered trimmer (up to 100″) is the answer. The PowerTech’s normal speed variant cuts at 0.5M/sec and is better for trimming heavier materials.

Optional Stand & Waste Catcher Package

This convenient quality steel stand that supports the Rotatrim PowerTech Series trimmers offers rigid support at the ideal working height of 34 inches. Black finished, this stand includes an integrated, transparent space-saving waste catcher that secures off cuts.

Helpful Hints

Two-way cutting option is available on all Rotatrim machines by removing the overload protection plate. The overload protection system ensures that it is virtually impossible to overload the machine. But, if cutting appropriate material, this plate can be removed in order to offer bi-directional cutting.